If you have multiple options, optimize your choice.You may choose any bend radius on this line(s).Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement).

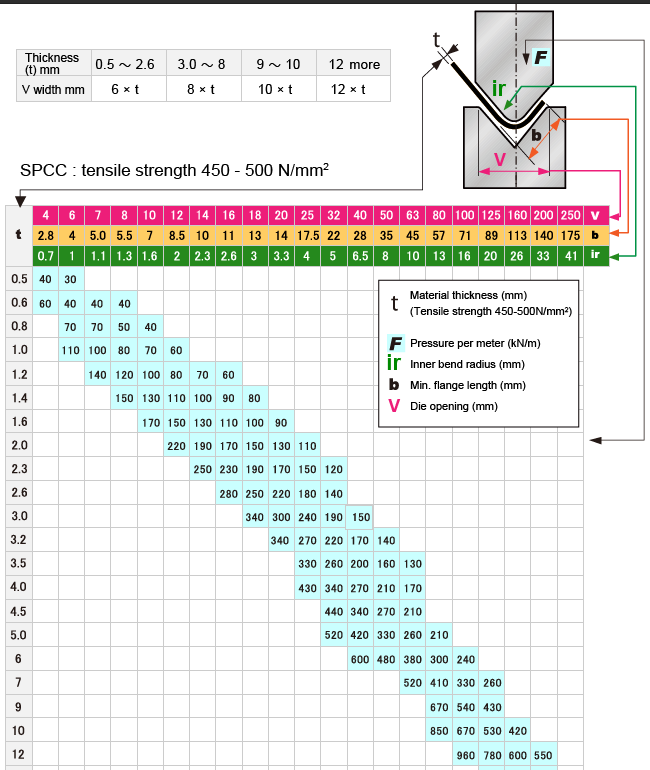

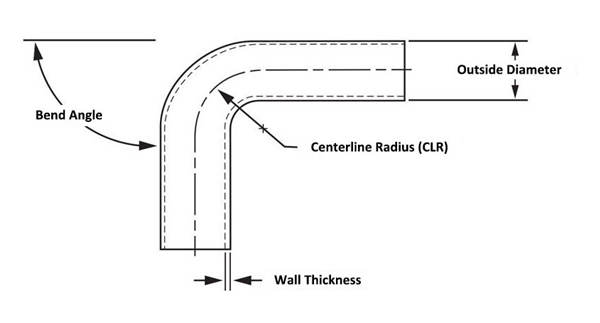

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. 6061T6 tubing cannot be coiled for shipping. Alternatively, you can design with any value, and we can adjust it for you later in the process. If you need help choosing a value, contact us at or 1-86 and we can help. Use this document to choose values that are both manufacturable and meet your needs. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Tony also mentions the 1T guideline in an article in the January '72 issue of Sport Aviation.( Watch More Tech Tip Videos) Bend Radii & Minimum Bend Sizes On page 44 of "Sportplane Construction Techniques" Bingelis shows the 1T as part of a table, and says the values were ".derived from reliable USAF and FAA references." Wonder our tool and die maker learned his trade at the same time as Tony. Might be that any slight cracking gets taken care of during this process.īeen discussing this on FB^2 (Fly Baby Facebook page), and while most folks posted about the online references saying 3T, 1T was echoed by a tool and die maker. On the Fly Baby, after making the bend, a piece of steel tubing is welded on the outside corner.

but going against Tony Bingelis' recommendation is dangerously close to tugging on Superman's cape or spitting into the wind. I can find all sort of online data to justify the 3T bend radius. Not all pieces are under the same sorts of stresses, and that, more than anything, matters the most, IMHO.Yeah, it's funny. I tend to squint an eye on one-size-fits-all guidance, as it really matters on application. Well, Ron, since I've never heard of a Fly Baby having gear problems, I reckon Tony is onto something.

0 kommentar(er)

0 kommentar(er)